This paper presents a case study of continuous productivity improvement of an automotive parts production line using Internet of Everything (IoE) data for fault monitoring. It is hoped that this work can provide a fundamental basis for researchers and industrial practitioners in adopting GbA-based PdM, and initiate several future research directions to achieve the cognitive PdM. Finally, challenges and future works toward cognitive PdM are proposed. Secondly, the implementation strategies and instances of GbA in PdM are presented. Firstly, GbA and their corresponding graph construction methods are introduced.

Aiming to fill this gap, this paper concentrates on GbA, and carries out a comprehensive survey organized by the sequential stages in PdM, i.e., anomaly detection, diagnosis, prognosis, and maintenance decision-making. However, despite its advantages, few papers discuss cognitive inference in PdM, let alone GbA. In addition, GbA can achieve promising performance on PdM's perception tasks by revealing the dependency relationship among parts/components of the equipment. To address this problem, graph-based approaches (GbA) with cognitive intelligence are proposed, because the GbA are superior in semantic causal inference, heterogeneous association, and visualized explanation. Meanwhile, complete correlation analysis of identified faults and the corresponding root causes is often missing. Many existing approaches have not been able to manage the existing knowledge effectively for reasoning the causal relationship of fault. Much attention to existing PdM research has been paid to perceiving the fault, while the identification and estimation processes are affected by many factors.

Predictive Maintenance (PdM) has continually attracted interest from the manufacturing community due to its significant potential in reducing unexpected machine downtime and related cost. Based on these ideas, we build a benchmarking system for smart candy packing application that supports direct consumer customization and flexible hybrid production, and the data are collected and processed in real time for fault diagnosis and statistical analysis. Then, we propose a scheme to integrate knowledge reasoning and semantic data where the reasoning engine processes the ontology model with real time semantic data coming from the production process. In this paper, we first define the smart factory as a cloud-assisted and self-organized manufacturing system in which physical entities such as machines, conveyors, and products organize production through intelligent negotiation and the cloud supervises this self-organized process for fault detection and troubleshooting based on data analysis.

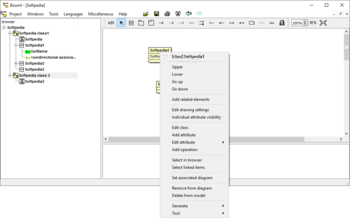

Bouml download Offline#

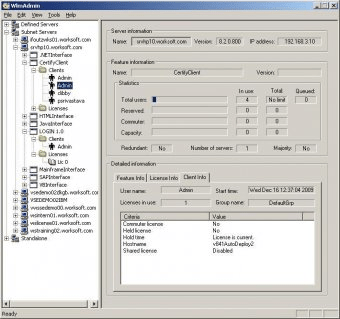

However, the currently existing architectures are mainly for offline data analysis, not suitable for real-time data processing. Industrial data analysis plays important roles in condition monitoring, performance optimization, flexibility, and transparency of the manufacturing system. The application of high-bandwidth networks and cloud computing in manufacturing systems will be followed by mass data.

0 kommentar(er)

0 kommentar(er)